- Experience and Engineering

- Liftek waterbags are Engineered from Experience. These are fabricated based on the experience of numerous crane load tests done for more than 20 years.

- Manufacturing Standards

- Manufactured in-house in Liftek’s custom built facility to DNV certified ISO 9001 system.

- Working Load Limit (WLL)

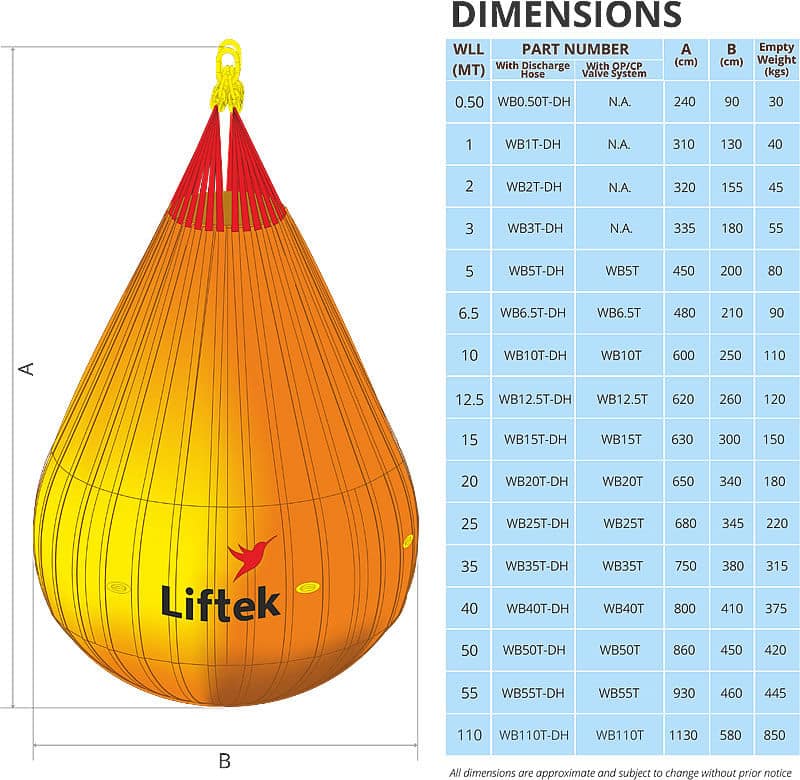

- WLL of Liftek Waterbags range from 0.25MT to 110MT.

- Material Construction

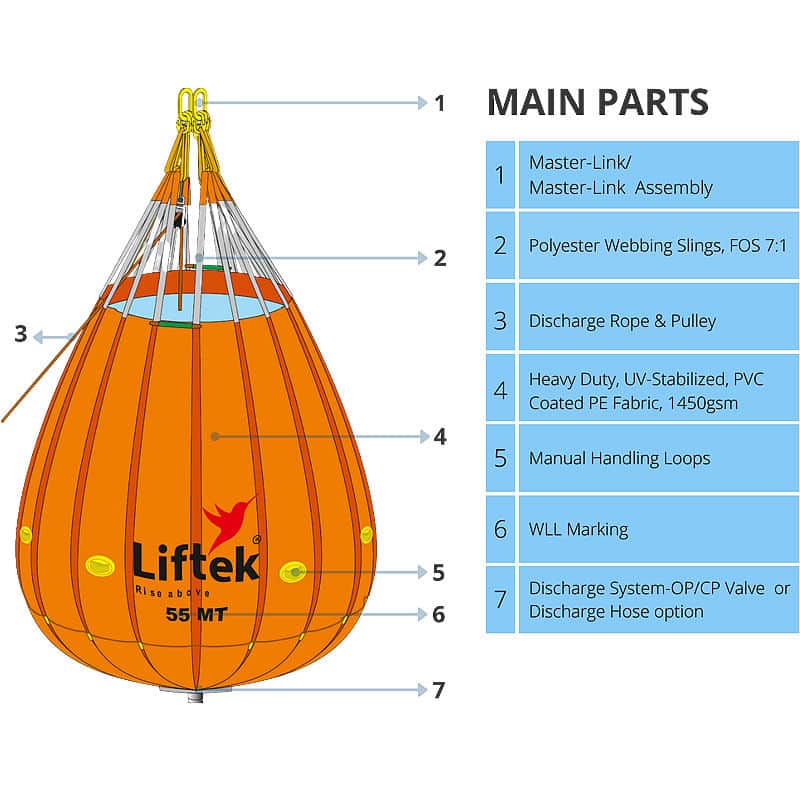

- Constructed from 1450gsm heavy duty UV-stabilized, PVC coated PE fabric. This offers the ideal combination of strength for load-tests, flexibility for storage and handling & durability for long-life.

- Discharge Options

- Liftek waterbags come with 2 options for discharging the water after usage, traditional and OP/CP Valve discharge mechanism.

- OP/CP Valve Discharge Mechanism

- The OP/CP Valve option enables the Open/Close control of the waterbag discharge by an easy single-pull of the rope and does not require a separate discharge hose to be installed.

- Lifting Set FOS

- The Lifting Set of all Liftek waterbags up to 55MT have a minimum FOS of 6:1 and 5:1 for 110MT.

- Proof Load Testing

- Lifting Set components of all Liftek Waterbags are proof loaded to 2 x WLL.

- Replaceable Components

- Lifting Set components that are worn or damaged are easily removable and replaced. Damaged fabric can be fixed with our Repair Kit.

Waterbag

Price available upon request

Available Variations

| Working Load Limit | Stock | Compare |

|---|---|---|

| 5 t | 25 | |

| 10 t | 25 | |

| 20 t | 25 | |

| 35 t | 25 |

| Manufacturer | Liftek |

|---|---|

| Certificate | Conformity |

| Buy or Rent | Buy |

| Condition | New |

| Location | UAE |

No data tables available

No documentation or downloads available

-

Spark Resistant Chain Block

Price range: $466,01 through $492,76Ships as early as 1 day from UAE -

TRCB Chain Block

$218,71Ships as early as 1 day from UAE -

Trolley Geared Twin Bar

Price range: $500,12 through $1.350,02Ships as early as 1 day from UAE -

Trolley Geared Single Bar Hand Chain

$285,31Ships as early as 1 day from UAE -

Trolley Geared Single Bar HC Drop

Price range: $150,27 through $191,31Ships as early as 1 day from UAE -

Trolley Geared Single Bar

$126,04Ships as early as 1 day from UAE

These latest additions might interest you

-

Navigational and Mooring Buoys (Various types)

-

Hi Tech Pneumatic Fenders – New

Price range: $3.200,00 through $21.000,00Ships as early as 14 days from India -

Rotary Vibrator Hose 5000PSI

$0,01Ships as early as 1 day from Kuwait -

DELTA / FLIPPER ANCHOR 3 TON – 16 TON

Price range: $1.950,00 through $10.000,00Ships as early as 1 day from UAE -

STS (Stevshark) 10 TON

Price range: $5.200,00 through $6.500,00Ships as early as 90 days from UAE -

Spark Resistant Chain Block

Price range: $466,01 through $492,76Ships as early as 1 day from UAE